In 2012, a silicone sealant manufacturer was seeking cartridge filling equipment which can proportionally add certain base materials and color pastes. This aims to solve the needs for multi-specification production.

Adopting traditional filling methods, the customer had great difficulties with raw material loss and controlling product quality.

Fills uniformly in color. No bubble occurs during the operating. High filling accuracy ensures low material loss. Easy operation.

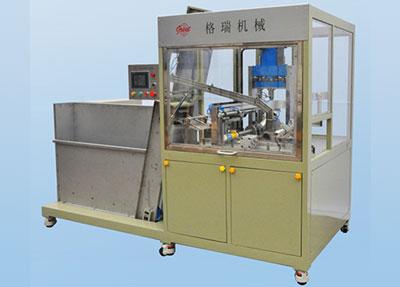

In order to meet the customer’s requirements, our technical staff developed and manufactured a piston filler with color mixer (GRQY-H3-300) on the basis of single head piston filler (GRQY-3500) and the mixing function of static mixer. This piston filler integrates functions of automatic empty cartridge feeding, automatic plunger feeding, static mixing and filling, plunger inserting and coding.

The fillers operates stably at present, with flexible operation and low material loss. No safety accidents occurred and the product quality was within the control scope.