- Home

- Filling Lines

Filling lines are made up of different filling machines, each of which offers its own specialized functions and interacts or coordinates with the other pieces of equipment. The lines work to complete automatic filling, packaging, encasing, and other processes. Great is able to provide customers with three filling lines, including the silicone sealant piston filling line, photovoltaic sealant filling line, and polyurethane sealant filling and packaging line. We can also recommend the best filling lines for meeting various demands.

-

Single Head Piston Filler

Single Head Piston Filler-

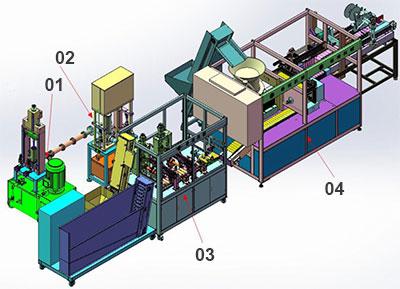

The silicone sealant piston filling machine consists of a 3K static mixer system, material pressuring system, dual head piston filler, plus automatic case erector and sealer. This filling line applies to the batch production of silicone sealant cartridge filling.

-

Filling System for Photovoltaic Sealant, Modified Silane Adhesive, Potting Sealant

Filling System for Photovoltaic Sealant, Modified Silane Adhesive, Potting Sealant-

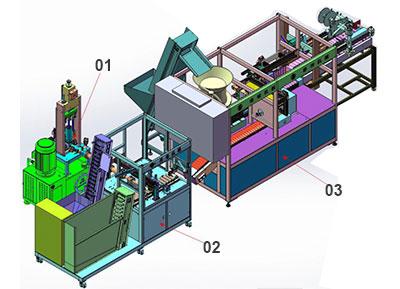

The filling system for photovoltaic sealant, modified silane adhesive and potting sealant is made up of a 3K static mixer, single head piston filler, plus automatic case erector and sealer. This filling system is applicable for batch production of photovoltaic sealant cartridge filling.

-

Filling and Packaging Line for Polyurethane Sealant

Filling and Packaging Line for Polyurethane Sealant-

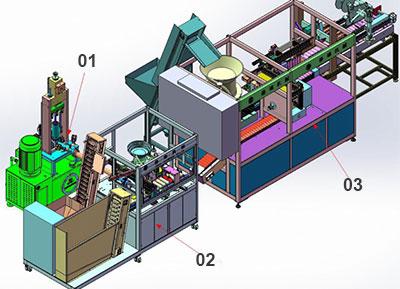

The Filling and packaging line for polyurethane sealant consists of a 3K static mixer, automatic aluminum tube piston filler, automatic case erector and sealer. And it can be used for the batch production of polyurethane sealant cartridge filling.