In 2016, a producer of silicone sealant required packaging equipment to match the double head piston filler (GRQY-320X2) for replacing manual operation.

- Each cartridge should be installed with sealant nozzle.

- Place a qualification and a warranty booklet in each box of products.

- The carton should be sealed up and bottom.

- Security identification label should be affixed on the seal of the carton.

- Two cartoning specification: 5×5 stacking mode, 25 cartridges/case; 4×6 stacking mode, 24 cartridges/case.

- The qualified installation rate of nozzle sealant is 100%.

- Product labeling and qualification adding rates are 100%.

- The carton seals are aligning, with a clearance less than 1.5mm.

- The qualified rate of the security identification label position is 100%.

- No damage in the outer packaging.

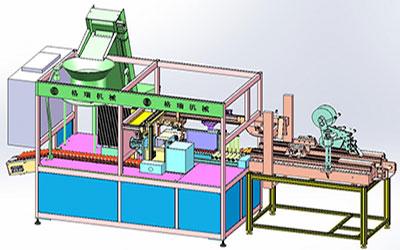

To meet the customer’s requirements, we developed and manufactured a filler integrating functions of sealant nozzle sorting and installing. Following the casing requirements, this equipment (GRBZ-65-A) has functions of stacking, automatic case opening, automatic label and qualification putting in, up and bottom case sealing and labeling anti-counterfeiting identification label.

Now, the filling line operates stably and each function running index meets customer’s requirements. The labor intensity of the worker is reduced. The labor intensity is lower than before even when the workers are reduced by 1-2 people.