- Home

- Factory Tour

Core accessories used in our products are supplied from international famous brands. Pneumatic hydraulic and other standard parts adopt the industry’s highest standard configuration to ensure stable operation. This also guarantees the quality of filled products while improving production efficiency.

- Programmable controller: Omron

- Human-machine interface: HITECH

- Low voltage electrical apparatus: Schneider

- Sensor: BALLUFF

- Servo motor: Panasonic

- Gear motor: JSCC

- Hydro-motor: SIEMENS, CHYUN TSEH

- Hydraulic oil pump: Rexroth, Yuken

- Hydraulic valve set: Rexroth, Yuken

- Cylinder: Rexroth, FESTO

- Pneumatic valve terminal: Rexroth, FESTO

- Compressed air preparation: Rexroth, FESTO

All the raw materials should be cut based on parts specification. The main cutting machine include automatic sawing machine and electric cutter.

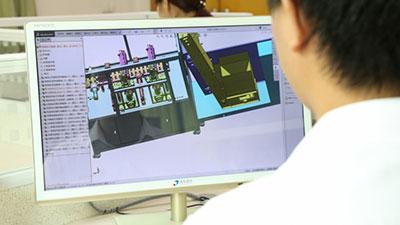

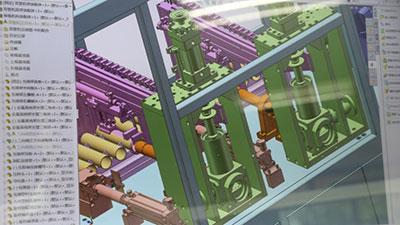

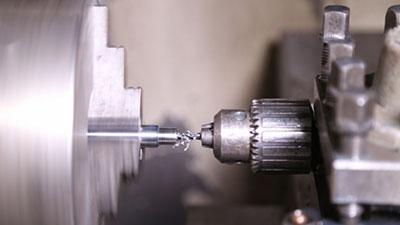

After cutting, the raw materials are transferred to machining workshop when the number and size are collected and quality-confirmed. Then the materials are machined step by step following processes. The main machining equipment includes CNC, CNC lathe, CNC electric discharge machine, CNC wire cutting, large grinder, different specifications of ordinary milling machine, automatic tapping machine, etc.

The employees are assembling the machines. All series of products are assembled in this workshop.

Each machined part will be inspected by a quality controller. Only qualified parts can enter the warehouse and be recorded by warehouse keeper.